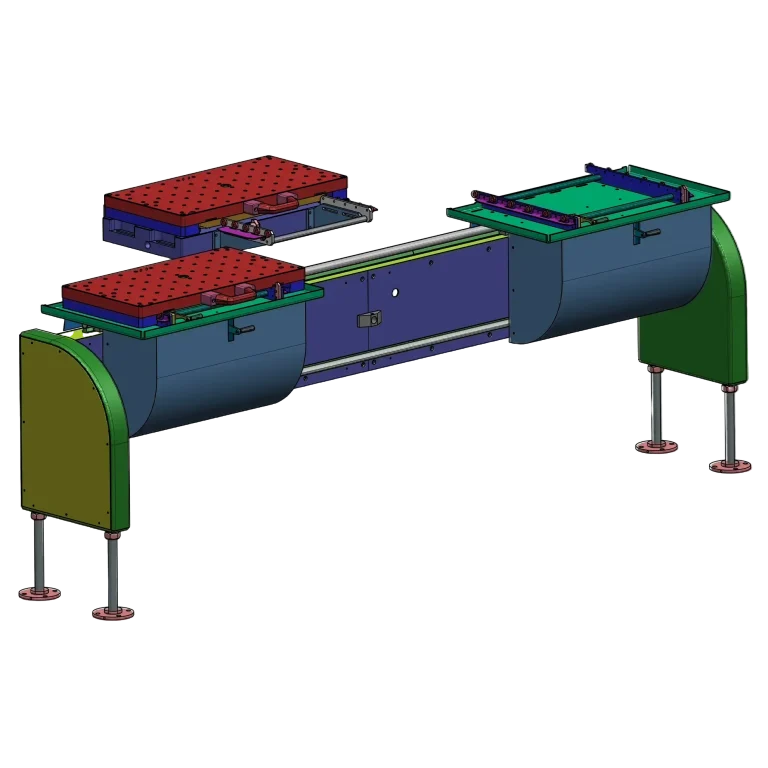

MANUAL PALLET CHANGER SYSTEM

Manual Pallet Changer System

The Manual Pallet Changer System ‘Set Up 100%’ is easily adaptable to any Vertical Machining Center, milling machine, grinding machine, 3D measuring machine or as a dual robotic welding station.

Robust and compact design, adjustable in height and length, the lower part remains free for access to the chip/coolant drawers.

CNC TO DOUBLE PALLET

Convert your Vertical Center CNC to a double pallet machine and improve production times and preparation of parts for machining.

ADAPTABLE AND EFFICIENT

Great flexibility and adaptability to any type of CNC machining centers, milling machines, robotics station, 3D measuring machines, Drills-Threading, etc.

REDUCE COSTS

Reduce more than 50% your manufacturing cost in preparing and useful machine and part-piece change.

Upgrade your Machining Center with the Manual Pallet Changer System Set Up 100%

- Convert your CNC vertical center to a double pallet machine

- Adaptable to all makes and models

- Reduce more than 50% its manufacturing cost

- Improve productivity and profitability

- Eliminate preparation time

- Forget changing times "piece by piece

- Pallet change 20" approx

Manual Pallet Changer System is the Perfect Solution for every Machine Tool

Robust and Compact Design

- Height and length adjustable to fit almost all makes and models of machine tools

- Load capacity of up to 500 kg. Operators can easily load and unload pallets in seconds

- Suitable for small, medium and large batches

- Significant increase in productivity without without additional operator input

- Reduced spindle downtime resulting in growing profits year over year

- Very simple installation and ready for production

- Positioning repeatability is less than 0.004 mm

- Higher productivity = lower costs